IT development for remote monitoring of heat treatment furnaces

This is a monumental industrial project, which combines unique software development with the industrial environment. An innovative solution was introduced into the production of transformers at Siemens Energy ltd.

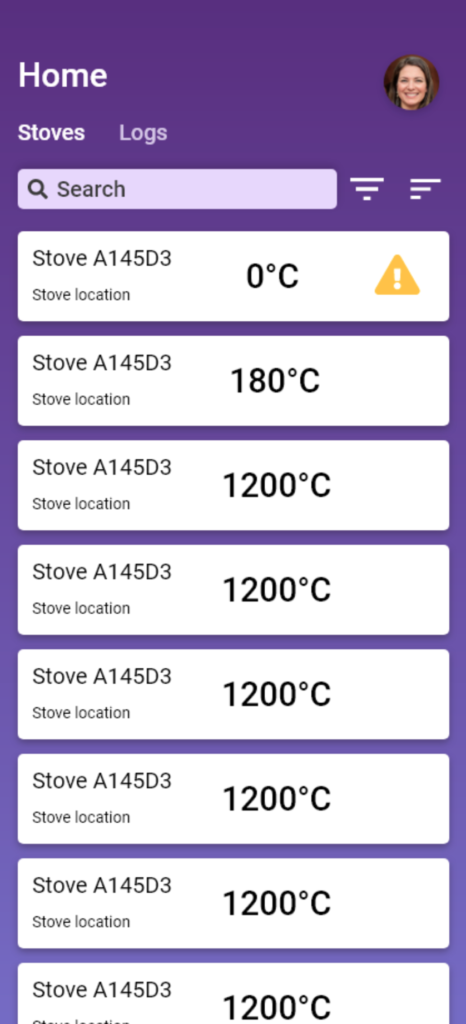

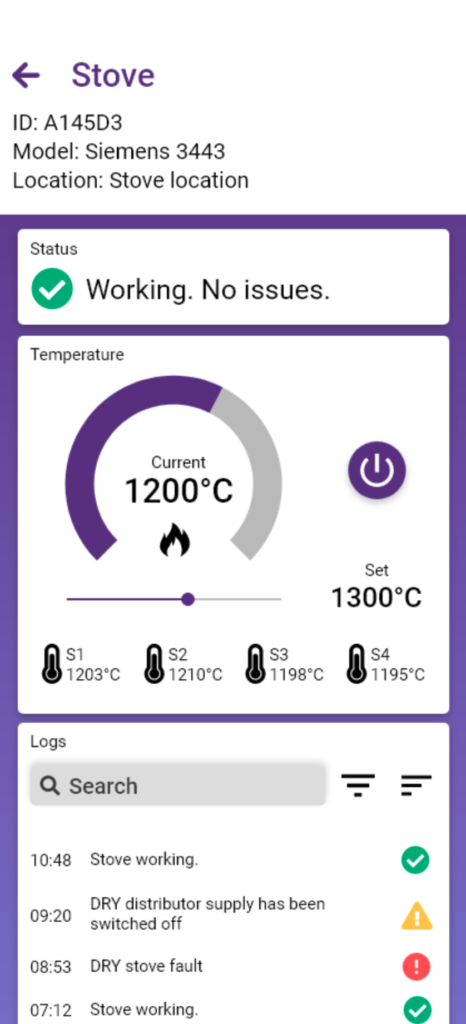

The aim of the project was to create a system using UPS for continuous power supply and remote control. This project consisted of the installation of the UPS, the development of the remote mobile application, and the connected industrial automation development for the remote monitoring. This bus connection collects the data of the stove’s regulator and stores it in the database.

The system which collects the data from the drying stove makes it feasible to interfere with the production to make sure the continuous capacity.

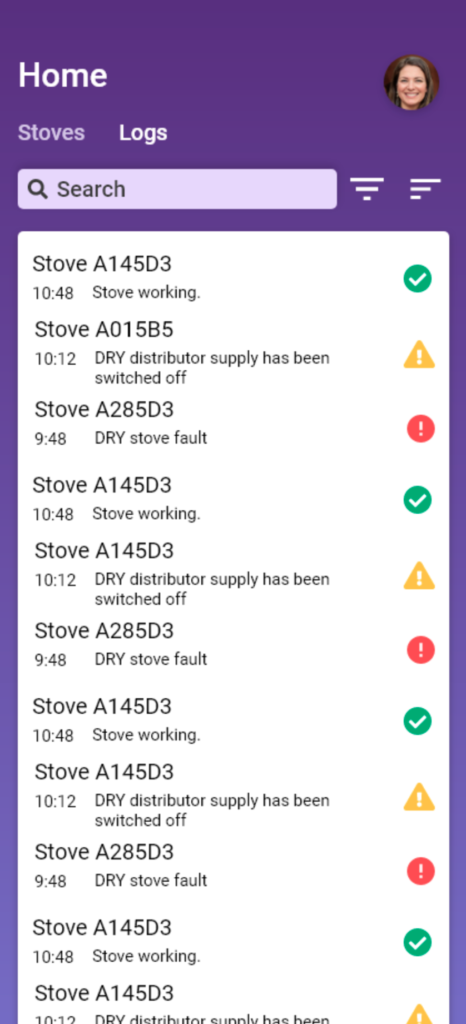

In the scope of the project not only unique software development was needed, but also onsite, automation, and power-current installation. The UPS ensures the continuous power supply in case of an outage and the application monitors the stove’s data and analyzes the updated information. It is also possible to check the history of the even in the application. Additionally, the system sends alarms in case of any events via emails and SMS, so all stakeholders can be informed immediately and it gives the opportunity to interfere which increases the quality and capacity of the production.

.

. During the project the following technology was used, PLC programming, MySQL, JVM(Java Virtual Machine). The team used the agile method during the development, which has the advantage of customer focus and continuous cooperation.

This method ensures the highest value delivery to the customer.

Similar systems can be used in the other area of the industry, where it is critical if the process is paused for a shorter time. This area can be the process where heating is involved.

Challenges during the project

.

.  .

.

Hardware acquisition and their integration into the enterprise ecosystem were some of the biggest challenges we have faced during development.

From a technological point of view, continuous development without interruptions (e.g. scheduled shutdowns without lost production) was the biggest challenge. The module installation of our automation system’s components could be solved by shutting down the industrial furnaces and then switching off the power completely. This posed serious logistical challenges for this large-scales and continuously working system, as cooling and reheating the furnaces could also cause production outages.

Integration of new components into the enterprise ecosystem sometimes took 3 times more than it has been estimated together with the Customer because of the workflows, decision-making mechanisms, and slow acquisition processes (planning and implementing the connected LAN and WAN communication platform)

The team had to adjust the deadlines and milestones taken into consideration the production cycles, continuously refining our workflow, and at times ramping up the team’s staffing.

Team Composition

The team has been built upon agile concepts and the composition was changed during the cooperation. During the complex Industry 4.0 development, it has been assigned 2 senior architects and software engineers: one on the industrial automation side and one for the rest of other covered fields as backend development, DevOps, mobile application development. The whole team has been split into two separated sub-team: automation as well as supporting development. Based on requirements and phase of development we have covered the following areas, using the following staffing:

UX/UI: 1 engineer

Industrial automation: 2-3 engineers

Backend development: 1 engineer

Mobile Application Development: 1 engineer

DevOps: 1 engineer

Testing: 1-2 test engineers

- UX/UI: 1 mérnök

- Ipari automatizálás: 2-3 mérnök

- Backend fejlesztő: 1 mérnök

- Mobil alkalmazás fejlesztés: 1 mérnök

- DevOps: 1 mérnök

- Tesztelés: 1-2 teszt mérnök

Kulcs lessons learned elemek

Preparation of Industry 4.0 type projects need extra dedicated time and perseverance in order to identify and minimize the risks, but it deserves the allocated times and will save time during development.

The continuous and transparent implementation process will help to find and solve even industry level challenges (eg. planned shutdowns, continuous production requirements, long shifted acquisition process, COVID-19 regulations an industrial ecosystem)

Results and feedback from our client

Thanks to delivering the flexible and stable solution, the Customer requested some additional development on top of Phase one development. These are expected to be delivered in 2022 R1

Technologies used on the project

Technologies

- Android SDK, PHP, Apache, MariaDB, OpenWRT, domvm, PLC programozás

Version Control

- Gitlab

Project Management Tool

- JIRA

Documentation

- Confluence

Communication Tools

- Microsoft Teams

Background

- Client: Siemens-Energy

- Year: 2021

- Sector: Industry

- Type: Industry 4.0

- Duration: 6 months

- Model: Hybrid

- Localisation: HU, EN, DE